Hand Tools

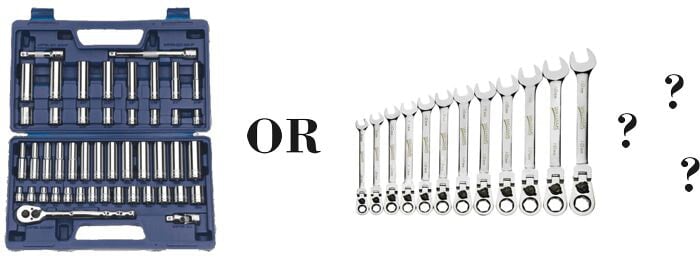

Socket vs. Wrench

When it comes to tackling mechanical and DIY projects, having the right tools at your disposal is essential for efficiency and effectiveness. Among the many tools available, sockets and wrenches are two standard options for tightening and loosening nuts, bolts, and fasteners. But which tool should you choose for a particular job? In this blog, we will delve into the differences between sockets and wrenches, their advantages and limitations, and provide insights to help you determine which tool is right for your specific task.

Sockets:

Sockets are versatile tools consisting of a cylindrical hollow shape that fits onto the head of a fastener. They are designed to be used with a socket wrench or ratchet handle, allowing for smooth and efficient operation.

Here are the advantages of using sockets:

- Wide Range of Sizes: Sockets come in various sizes to accommodate different nut and bolt dimensions, offering versatility for various applications.

- Torque Application: Sockets, when paired with a socket wrench or ratchet handle, allow for precise torque application, making them suitable for tasks that require specific tightening or loosening specifications.

- Accessibility: Sockets can reach nuts and bolts in tight or confined spaces due to their slim design and ability to attach to an extension bar or flex joint.

- Grip and Stability: Sockets provide a secure grip on fasteners, reducing the risk of slippage and damage to both the tool and the fastener.

Wrenches:

Wrenches, also known as spanners, are handheld tools with an adjustable or fixed end for gripping nuts, bolts, and other fasteners.

Here are the advantages of using wrenches:

- Simplicity and Portability: Wrenches are simple and straightforward tools, making them easy to use and carry around. They are ideal for quick repairs or tasks on the go.

- Versatility: Adjustable wrenches, such as crescent wrenches, can accommodate a range of fastener sizes, providing flexibility for various applications without needing multiple tools.

- Greater Torque: Wrenches, especially longer-handled versions, offer increased leverage and torque, making them suitable for stubborn or heavily tightened fasteners.

- No Socket Size Restrictions: Wrenches can handle fasteners with non-standard or unconventional sizes that may not have corresponding sockets.

Choosing the Right Tool:

To determine whether a socket or a wrench is the right tool for a particular job, consider the following factors:

- Accessibility: Evaluate the space constraints and accessibility of the fastener. A socket with an extension bar may be the best choice if the nut or bolt is located in a tight or confined space.

- Size and Torque Requirements: Determine the size of the fastener and the torque specifications for the task. If precision torque application is crucial, sockets with a socket wrench are preferred. For quick repairs or general applications, a wrench can suffice.

- Fastener Type: Consider the type of fastener you are working with. Sockets are ideal for hexagonal or square-shaped fasteners, while wrenches are versatile for various shapes, including square, hexagonal, or rounded.

- Project Complexity: Assess the complexity of the project. A wrench may be sufficient for simple repairs or tasks requiring minimal torque. For more complex projects or applications with specific torque requirements, sockets with a socket wrench provide better control.

Conclusion:

Both sockets and wrenches are valuable tools in any toolbox, each with its own advantages and limitations. The choice between the two depends on accessibility, size and torque requirements, fastener type, and project complexity. By understanding the strengths of each tool, you can make an informed decision and select the appropriate tool for your specific job, ensuring efficient and successful completion of your mechanical and DIY projects.