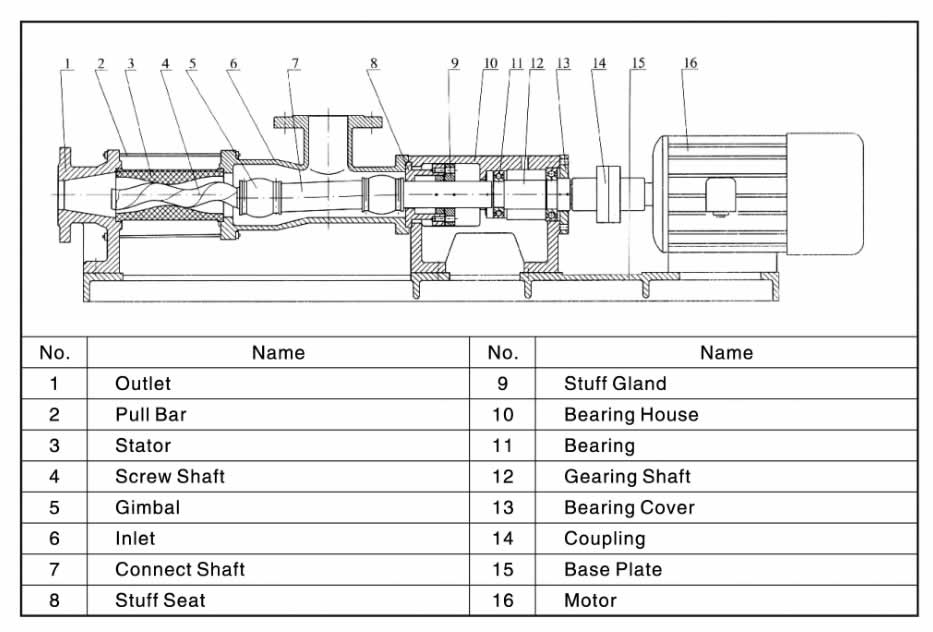

Mono pumps, known for their reliability in handling a variety of fluids, are widely used in industries such as wastewater treatment, food processing, and chemical manufacturing. To ensure these pumps operate efficiently, it is crucial to understand the various mono pump parts and their functions.

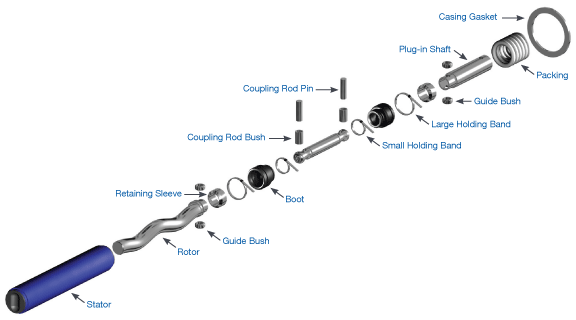

- Stator

The stator is a key component of the mono pump. It surrounds the rotor and creates the cavities necessary for fluid movement. Typically made from a softer material, the stator deforms slightly around the rotor, facilitating efficient pumping. Over time, wear and tear can occur, especially in abrasive applications, necessitating regular inspection and timely replacement to maintain performance. - Rotor

The rotor is another critical part, responsible for generating the flow of fluid. It rotates within the stator, creating a series of chambers that move the fluid through the pump. A damaged or worn rotor can lead to decreased efficiency, so regular checks are essential to prevent operational issues. - Seals

Seals are designed to prevent fluid leakage and maintain pressure within the pump. They are vital for ensuring safe and efficient operation. Worn or damaged seals can result in significant losses and safety hazards, making immediate replacement a necessity. - Bearings

Bearings support the rotor and allow it to rotate smoothly. They play a crucial role in reducing friction and minimizing wear on the pump components. Regular maintenance of bearings is important, as worn bearings can lead to vibration and increased energy consumption. - Suction and Discharge Ports

These ports connect the mono pump to the piping system, facilitating fluid entry and exit. Ensuring these components are free from blockages and damage is vital for maintaining the overall efficiency of the pump. - Drive Unit

The drive unit powers the rotor’s rotation and can be electric or hydraulic, depending on the application. Understanding the drive unit’s function and maintenance needs is essential for consistent pump performance.

In conclusion, a comprehensive understanding of mono pump parts is crucial for operators aiming to maintain peak performance. Regular inspections and timely replacements of key components such as the stator, rotor, seals, and bearings help ensure the longevity and reliability of mono pumps. Prioritizing maintenance allows industries to reduce downtime and enhance productivity, contributing to overall operational success.