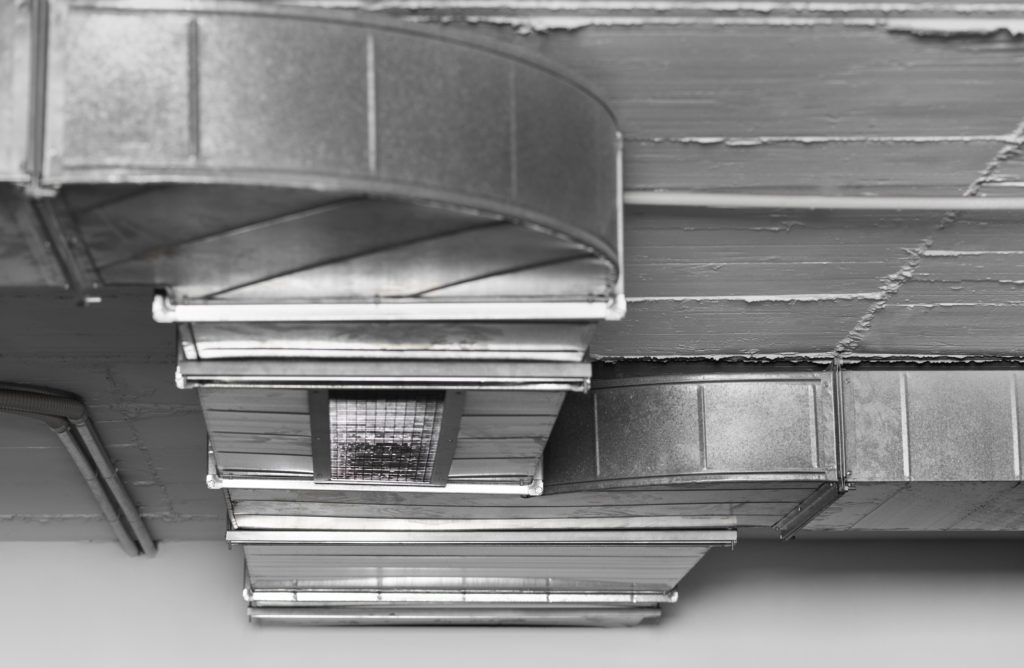

Ductwork fabrication

plays a crucial role in HVAC systems, as it involves the creation of ducts that

distribute conditioned air throughout buildings. To ensure efficient and

high-quality fabrication, it is essential to have the right tools and equipment

at your disposal. In this blog post, we will explore the must-have tools and

equipment for ductwork fabrication and discuss their importance in achieving

optimal results.

Basic Tools for Ductwork Fabrication

- Tape Measure and Ruler: Accurate measurements are vital in ductwork fabrication. A reliable tape measure and ruler enable you to precisely determine the dimensions of duct sections, ensuring a proper fit and efficient airflow.

- Sheet Metal Snips: These specialized cutting tools allow you to easily cut through sheet metal, enabling you to shape and trim duct sections as needed.

- Aviation Snips: Aviation snips are designed for cutting curved and straight patterns in sheet metal. They are indispensable when working on intricate duct designs or making precise cuts.

- Hand Seamers: Hand seamers are used to create tight and secure joints in the ductwork. They are especially useful for bending and crimping sheet metal to form durable connections.

- Duct Crimpers: Duct crimpers help create longitudinal crimps, which strengthen duct connections and prevent air leakage. They are essential for maintaining the integrity of the duct system.

- Duct Notchers: Duct notchers are used to cut notches or grooves into ductwork, allowing for easy assembly and precise fitting of duct sections.

Advanced Tools for Ductwork Fabrication

- Plasma Cutter: A plasma cutter provides precision cutting of various thicknesses of sheet metal. It enables swift and accurate fabrication, making it an efficient tool for large-scale projects.

- Duct Cutting Machine: A duct cutting machine automates the process of cutting duct sections to specific lengths, saving time and ensuring uniformity in fabrication.

- Duct Folding Machine: This machine assists in folding and bending sheet metal, allowing you to create complex duct shapes with ease.

- Duct Grooving Machine: A duct grooving machine helps create grooves or flanges along the edges of duct sections, facilitating secure connections and airtight seals.

- Duct Flanging Machine: A duct flanging machine forms flanges on the ends of duct sections, simplifying the process of joining multiple ducts together.

- Duct Beading Machine: This machine adds beads to the edges of duct sections, enhancing their structural integrity and reducing the risk of air leakage.

Specialized Equipment for Ductwork Fabrication

- Roll-Forming Machines: Roll-forming machines shape sheet metal into specific profiles, allowing for the production of spiral or rectangular ducts with precision and efficiency.

- Lock-Forming Machines: Lock-forming machines create the lock seam, a standard joint used in ductwork fabrication, ensuring a secure connection and preventing air leaks.

- Spiral Tube Formers: Spiral tube formers automate the process of producing spiral ducts, significantly reducing fabrication time and ensuring consistent quality.

- Automated Duct Assembly Systems: These systems streamline the assembly of duct sections, minimizing labor and increasing productivity.

- Duct Sealing Machines: Duct sealing machines apply sealants and adhesives to duct joints, ensuring airtight seals and preventing air leakage.

- Duct Cleaning Equipment: Duct cleaning equipment helps maintain the cleanliness and hygiene of fabricated ductwork, ensuring optimal indoor air quality.

Safety Equipment for Ductwork Fabrication

- Safety Glasses: Eye protection is essential when working with sheet metal, as it guards against debris and sparks.

- Gloves: Proper hand protection is crucial to prevent cuts, punctures, and other injuries while handling sheet metal and operating tools.

- Ear Protection: Ductwork fabrication often involves noisy machinery, so wearing ear protection helps prevent hearing damage.

- Respiratory Masks: Since ductwork fabrication generates dust, fumes, and particles, wearing respiratory masks safeguards against inhaling harmful substances.

- Protective Clothing: Durable and flame-resistant clothing protects against sharp edges, sparks, and heat.

- First Aid Kit: Having a well-equipped first aid kit on hand ensures prompt treatment of minor injuries that may occur during fabrication.

Essential Accessories for Ductwork Fabrication

- Layout Tools: Chalk lines and marking tools assist in precise measurements and marking of duct sections, ensuring accuracy in fabrication.

- Deburring Tools: Deburring tools remove sharp edges and burrs from cut metal, promoting safety and preventing damage to the duct system.

- Screwdrivers and Wrenches: These basic hand tools are indispensable for assembling and securing various components of the ductwork.

- Rivet Guns and Rivets: Rivet guns and rivets provide a sturdy and reliable method for joining duct sections together, ensuring durability and structural integrity.

- Clamps and Fasteners: Clamps and fasteners hold duct sections in place during fabrication and installation, ensuring stability and alignment.

- Mobile Workstations and Storage Solutions: Portable workstations and organized storage systems enhance efficiency by providing a dedicated space for tools and materials, allowing for easy access and minimizing downtime.

Maintenance and

Care of Tools and Equipment: To ensure the longevity and optimal performance of

your tools and equipment, it is essential to follow proper maintenance

practices, including regular cleaning, lubrication, and rust prevention.

Sharpening and replacing blades when necessary, as well as storing tools in a

clean and organized manner, contribute to their longevity and ensure they are

ready for use when needed.

Tips for

Choosing the Right Tools and Equipment: When selecting tools and equipment for

ductwork fabrication, consider the specific requirements of your projects,

balancing them with your budget. Evaluate the durability and quality of the

tools, read user reviews, and seek advice from professionals in the field.

Investing in reputable brands and tools with warranties can provide added

assurance of their performance and reliability.

Conclusion

Ductwork

fabrication is a crucial aspect of HVAC systems, and having the right tools and

equipment is essential for achieving efficiency and quality in fabrication.

Whether you are working on small-scale projects or large-scale installations,

utilizing the essential tools, advanced machinery, specialized equipment, and

safety gear outlined in this blog post will ensure that your ductwork

fabrication endeavors are successful. Remember to prioritize regular

maintenance and care of your tools and make informed decisions when selecting

new equipment. With the right tools and equipment, you can optimize your

ductwork fabrication process and deliver exceptional results for your clients.

Related Post:

-

Sheet Metal Fabrication Trends 2024: What to Watch For

-

How the Electric Vehicle market is driving changes in sheet metal fabrication technology

-

Sheet Metal Bend Relief Guidelines: Ensuring Successful Fabrication

-

Cold Rolled Steel Sheets vs. Hot Rolled Steel Sheets: Which is Right for Your Project?

-

Sheet Metal Bending in Architectural Design: Transforming Buildings with Curved Metal