10 Types of Circular Saws + Characteristics & Usages

(adsbygoogle = window.adsbygoogle || []).push({});

Table of Contents

In the vast world of tools and machinery, circular saws stand out as one of the most versatile and essential tools for both DIY enthusiasts and professionals. Whether you’re looking to make a quick rip cut or need a precise crosscut, the right circular saw can make a world of difference. At Linquip, we pride ourselves on connecting you with a comprehensive range of these indispensable tools.

TLDR

- Introduction: Linquip provides a comprehensive guide to the diverse world of circular saws.

- Types of Saws:

- Sidewinder: Lightweight, general-purpose.

- Worm Drive: Powerful, for heavy-duty tasks.

- Hypoid: High power, low maintenance.

- Cordless: Portable, battery-powered.

- Trim: Small, for precise tasks.

- Abrasive: For hard materials like metal and masonry.

- Biscuit Joiners: For wood joining.

- Metal Cutting: For metals like steel and aluminum.

- Concrete: For stone, brickwork, and concrete.

- Brushless Motor: Efficient, longer lifespan.

- Blade Selection: Match the blade type (e.g., carbide-tipped, diamond-tipped) to the material for optimal performance.

- Advanced Features: Modern saws may offer laser guides, electric brakes, and adjustable base plates.

- Buying Tips: Start simple, prioritize safety, and consult reputable brands. Linquip can be a reliable platform for reviews and expert insights.

- Conclusion: Linquip’s platform aids in selecting the right circular saw for various needs, ensuring quality and expertise.

Types of Circular Saws

- Sidewinder

- Worm Drive

- Hypoid

- Cordless

- Trim

- Abrasive

- Biscuit Joiners

- Metal Cutting

- Concrete

- Brushless Motor

Types of Circular Saws Table with Characteristics and Usage

| Type of Saw | Characteristic | Usage |

|---|---|---|

| Sidewinder | Lightweight, motor sits alongside the blade. | General-purpose cutting. |

| Worm Drive | The motor behind the blade offers more torque. | Heavy-duty tasks, long rip cuts. |

| Hypoid | Uses hypoid gears, a sealed system for lubrication. | Powerful cuts, less maintenance required. |

| Cordless | Battery-powered, highly portable. | Jobs requiring portability, light-medium tasks. |

| Trim | Small size, typically 3-1/2 inches blade diameter. | Precision cutting, finish work. |

| Abrasive | Uses a composite blade like a grinding wheel. | Cutting hard materials: metal, masonry. |

| Biscuit Joiners | Designed for making slots in wood. | Wood joining for strong connections. |

| Metal Cutting | Hard metal or carbide-tipped blade. | Clean cuts on metals: steel, and aluminum. |

| Concrete | Uses diamond-tipped blades. | Cutting concrete, stone, and brickwork. |

| Brushless Motor | Features a brushless motor for efficiency. | Long-term usage, especially for professionals. |

This table offers a quick reference to the types of circular saws, their defining characteristics, and their primary uses.

Sidewinder Circular Saws

Also known as: Standard circular saws

Characteristics:

- Motor Position: The motor sits alongside the blade.

- Weight: Generally lighter than other types.

- Speed: Spins faster due to direct-drive motor.

Best for: General-purpose cutting, particularly for those on the move, due to its lightweight.

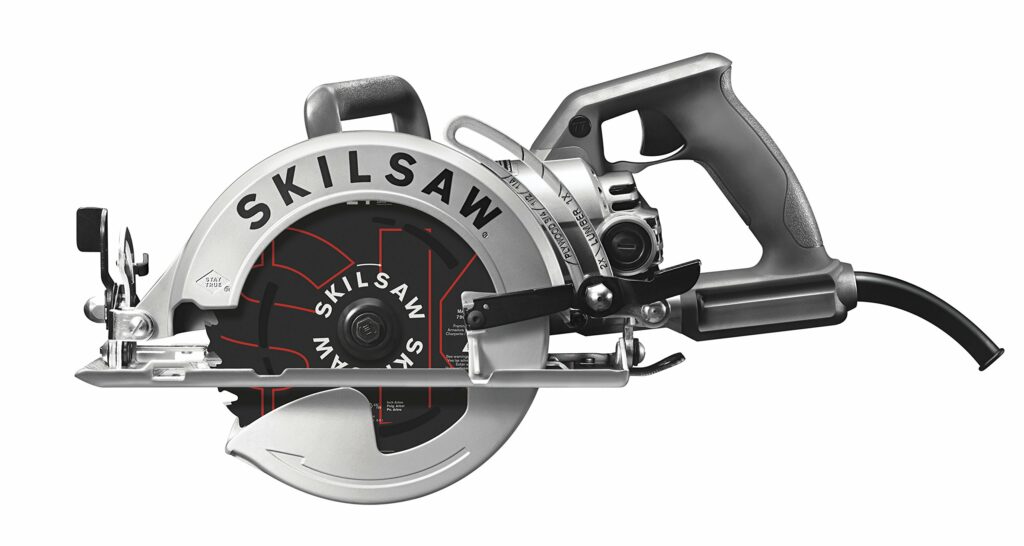

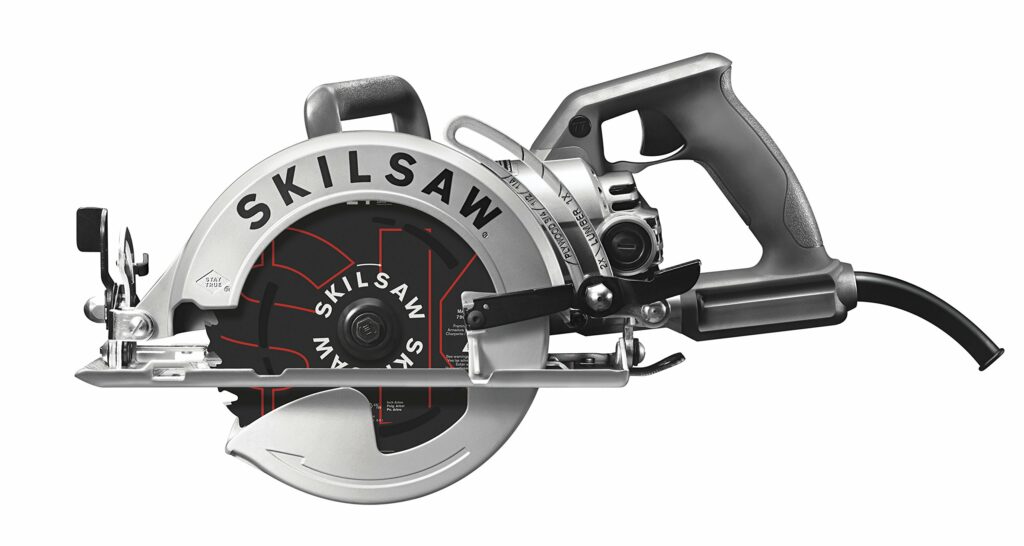

Worm Drive Circular Saws

Characteristics:

- Motor Position: The motor is located behind the blade.

- Torque: Provides more torque than sidewinders.

- Design: Long, narrow body.

Best for: Heavy-duty jobs and long rip cuts. Preferred by professionals for its power.

Hypoid Circular Saws

Characteristics:

- Gear Configuration: Uses hypoid gears.

- Lubrication: Sealed system, requires less maintenance.

- Torque: Similar to worm drive but slightly quieter.

Best for: Professionals looking for a powerful saw with less maintenance.

Cordless Circular Saws

Characteristics:

- Power Source: Battery-powered.

- Portability: Highly portable due to no power cord.

- Use Duration: Limited by battery life.

Best for: Jobs where portability and freedom from cords are a priority. Suitable for light to medium tasks.

Trim Circular Saws

Also known as: Dinky saws

Characteristics:

- Size: Smaller in size.

- Blade Diameter: Typically 3-1/2 inches.

- Function: Designed for finish work.

Best for: Trim work, paneling, and any job that requires a smaller, more precise cut.

Abrasive Circular Saws

Characteristics:

- Blade Material: Typically a composite, like a grinding wheel.

- Function: Designed to cut metal or masonry.

- Cooling System: Many have built-in systems to prevent overheating.

Best for: Cutting hard materials like metal, concrete, or tile.

Biscuit Joiners

Also known as Plate joiners

Characteristics:

- Function: Designed to make slots for joining two pieces of wood with a biscuit.

- Precision: Has adjustable settings for different biscuit sizes and depths.

Best for: Woodworking tasks where strong, unobtrusive joints are essential.

Sure, let’s expand our guide with more types and deeper insights.

Table: A Quick Comparison

| Type of Saw | Best for | Portability | Power Source |

|---|---|---|---|

| Sidewinder | General-purpose cutting | High | Corded/Cordless |

| Worm Drive | Heavy-duty, long rip cuts | Medium | Corded |

| Hypoid | Powerful tasks with less maintenance | Medium | Corded |

| Cordless | Jobs requiring high portability | High | Battery |

| Trim | Precision cutting & finish work | High | Corded/Cordless |

| Abrasive | Cutting metal or masonry | Low | Corded |

| Biscuit Joiners | Wood joining | Medium | Corded |

Safety Tips When Using Circular Saws

- Eye Protection: Always wear safety goggles to protect from flying debris.

- Hand Protection: Wear gloves to ensure a firm grip and prevent splinters.

- Check Before Cutting: Ensure the blade is sharp, undamaged, and appropriate for the material.

- Maintain a Stable Position: Use both hands, keep your footing, and ensure the material being cut is stable.

Maintaining Your Circular Saw

- Regular Cleaning: Remove dust and debris after each use.

- Blade Replacement: Dull blades can be dangerous and inefficient. Change them as needed.

- Lubrication: Ensure moving parts are well-lubricated, especially for worm drive and hypoid saws.

Metal Cutting Circular Saws

- Blade Type: Hard metal or carbide-tipped blade.

- Function: Specially designed for cleanly cutting metals without producing much heat.

- Safety Features: Often come with a chip collector to prevent metal shavings from flying.

Best for: Precise and clean cuts on metals like steel, aluminum, and copper.

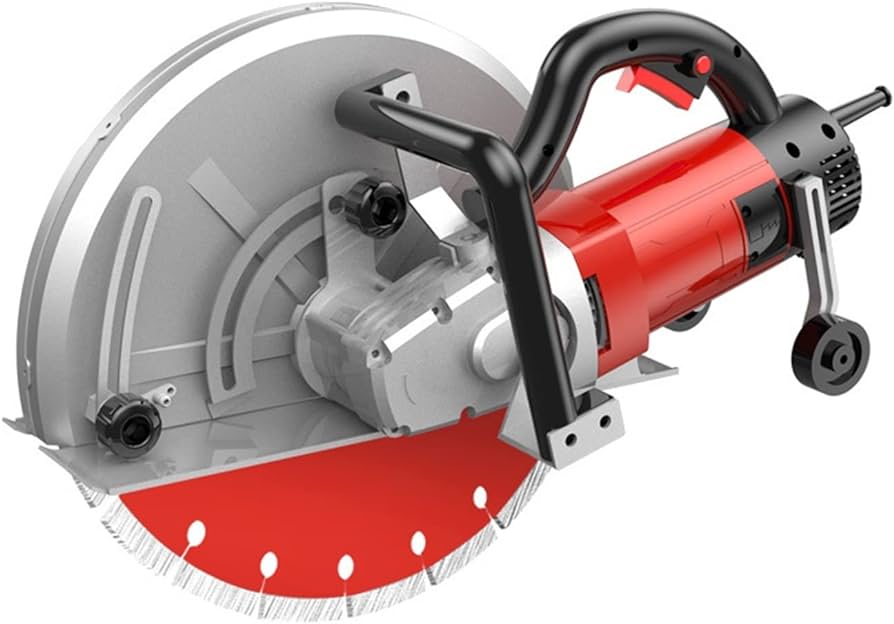

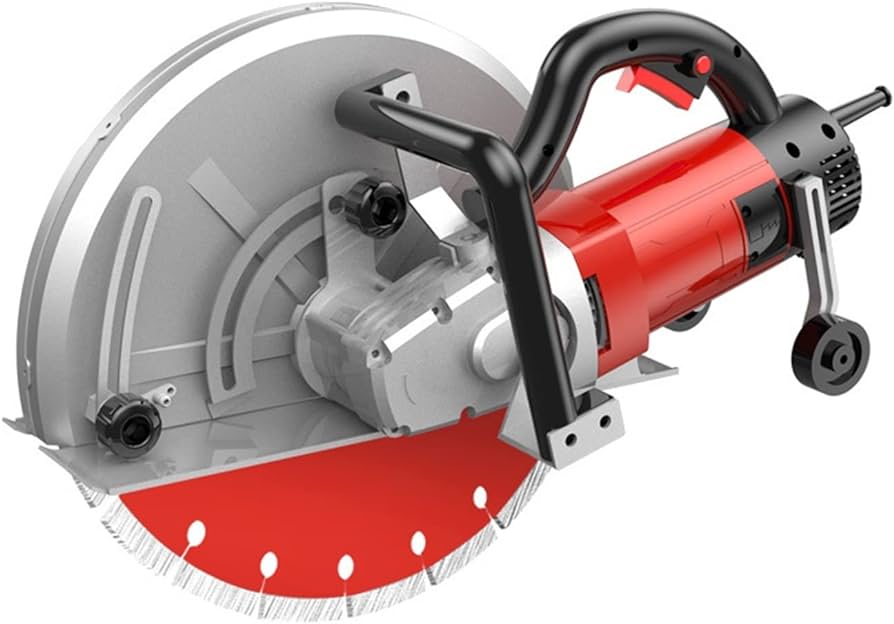

Concrete Circular Saws

Characteristics:

- Blade Type: Diamond-tipped blades.

- Function: Designed to handle the rigidity and density of concrete and stone.

- Cooling System: Many models come with a water hook-up to keep the blade cool and reduce dust.

Best for: Construction tasks involving concrete, stone, or brickwork.

Brushless Motor Circular Saws

Characteristics:

- Motor Type: Uses a brushless motor for increased efficiency and longevity.

- Performance: Less friction, more power, and longer lifespan compared to brushed motor saws.

- Battery Usage: Often optimized for better battery performance.

Best for: Long-term usage, especially for professionals who need their tools to last.

Choosing the Right Blade for Your Circular Saw

Your circular saw is only as effective as the blade you use. Here are some considerations:

- Material Type: Different materials require different blades. For instance, woods typically use carbide-tipped blades, metals need a metal blade, and masonry requires a diamond-tipped blade.

- Tooth Count: More teeth generally produce a smoother cut, while fewer teeth remove material faster.

- Kerf Width: Thin kerf blades remove less material, offering faster, more efficient cuts, while full-kerf blades are sturdier and might result in straighter cuts.

Advanced Features in Modern Circular Saws

- Laser Guide: Offers a laser line for more accurate cutting.

- Electric Brakes: Reverses the flow of electricity when the trigger is released, halting the blade’s momentum quickly.

- Adjustable Base Plates: Allows for bevel cuts at various angles.

Expert Tips for First-time Circular Saw Buyers

- Start Simple: For beginners, a standard sidewinder circular saw is often sufficient.

- Evaluate Needs: Consider the materials you’ll mostly be cutting and choose accordingly.

- Safety First: Opt for models with safety features like electric brakes and blade guards.

- Brand Reputation: Consider brands known for durability and performance. Consulting Linquip’s extensive platform can guide you through user reviews and expert insights.

Conclusion

Whether you’re venturing into a new DIY project or scaling up in professional construction, having the right circular saw is crucial. As the world of circular saws continues to evolve, so does Linquip’s commitment to offering comprehensive insights and a vast array of choices. By placing your trust in Linquip, you’re ensuring a blend of quality, knowledge, and excellence. Join us in navigating the intricacies of machinery, and let your projects shine with precision and efficiency.

Download PDF for Types of Circular Saws

A PDF version of the article can be downloaded by clicking the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 19 Types of Saws + Characteristic & Usage

- 8 Types of Bandsaws + Their Usage & Characteristic

- 4 Types of Miter Saws + Features & Usages

- 4 Types of Chop Saws + Applications & Characteristics

- 10 Types of Hose Clamps + Design, Applications & Advantages

- 12 Types of Latches with Their Benefits & Usages

- 10 Types of Wire Strippers + Table with Characteristics and Usage

- 13 Types of Tachometers With Their Functions & Advantages

- 8 Types of Anchors in Industry + Usages & Characteristics

- 15 Types of Protractors and Their Characteristics & Usages

- 9 Types of Threading Tools + Table with Characteristics and Usage

- 12 Types of Pipe Benders and Their Characteristics

- 14 Types of Shelves And Their Characteristics & Benefits

- 12 Types of Magnifiers + Table with Characteristics and Usage

- 7 Types of Airbrush + Table with Characteristics and Usage

- 14 Types of Nails With Features & Usages

- 14 Types of Automotive Tools + Table with Characteristics and Usage

- The 10 Best Circular Saws in the USA in 2022

- The 7 Best Jigsaw + Buying Guide

- The 7 Best Portable Band Saws + Tips for Choosing

- The 10 Best Chain Saw Sharpener

- The 10 Best Miter Saw + Guide Select

- The 10 Best Electric Chainsaw + Buying Guide

- The 8 Best Hand Saw

- 12 Types of Electric Saws: Clear Guide

- Different 15 Types of Hand Saws: Clear Guide

- 5 Types of Metal Cutting Saws + Features & Applications

- The 15 Best Reciprocating Saw in + Review

- 14 Types of Shelves And Their Characteristics & Benefits

- 12 Types of Magnifiers + Table with Characteristics and Usage

- 7 Types of Airbrush + Table with Characteristics and Usage