Progressive cavity pumps have gained significant popularity across various industries due to their unique ability to handle a wide range of fluids, including viscous and shear-sensitive materials. While the initial investment in progressive cavity pump parts can be considerable, understanding their value and long-term benefits is essential for making informed decisions. This article explores the worth of investing in progressive cavity pump parts, examining their advantages, applications, and the overall impact on operational efficiency.

Understanding Progressive Cavity Pumps

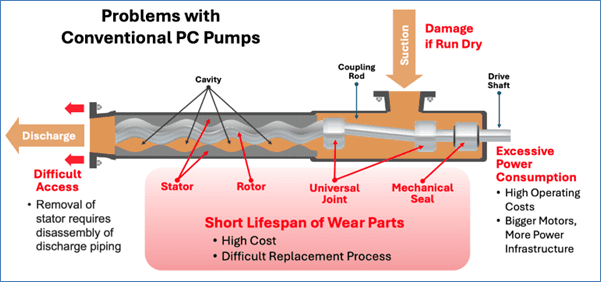

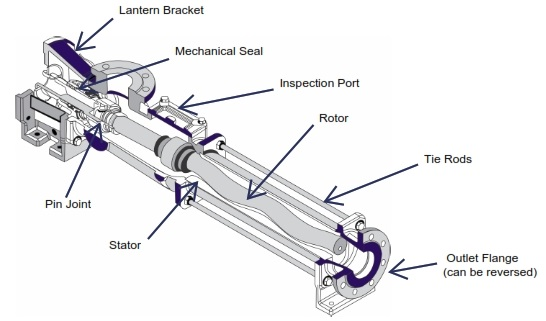

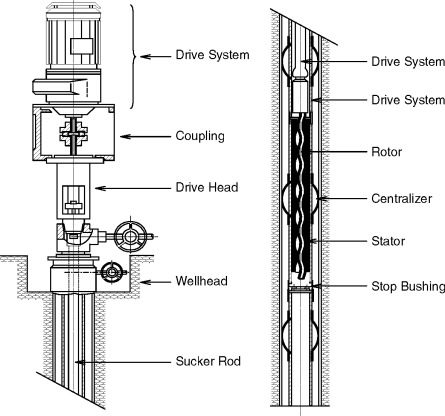

Progressive cavity pumps consist of a helical rotor and a stator that work together to transport fluids. This design allows the pump to create a smooth, continuous flow, making it ideal for applications that require high precision and reliability. The effectiveness of these pumps largely depends on the quality of their parts, which directly influences their performance and longevity.

Advantages of Progressive Cavity Pump Parts

1. Reliability and Consistency

One of the primary advantages of progressive cavity pump parts is their ability to provide consistent flow rates. Unlike other types of pumps, which may experience pulsation or fluctuations in flow, progressive cavity pumps deliver a steady output. This reliability is critical in industries such as food processing, wastewater treatment, and chemical manufacturing, where precise flow rates are essential for maintaining product quality and compliance with regulations.

2. Versatility

Progressive cavity pumps are versatile and capable of handling a wide range of fluids, from low-viscosity liquids to highly viscous sludges. The ability to pump abrasive, corrosive, or shear-sensitive materials without damaging the fluid makes these pumps particularly valuable in specialized applications. Investing in quality pump parts ensures that they can accommodate various fluid types and conditions, enhancing their usability across different processes.

3. Reduced Maintenance Costs

High-quality progressive cavity pump parts can lead to reduced maintenance costs over time. While the initial investment may be higher, durable components often require less frequent replacement and repair. This longevity minimizes downtime and the associated costs of service interruptions. Regular maintenance, coupled with robust parts, can significantly enhance the overall lifespan of the pump.

4. Energy Efficiency

Efficiency is a critical consideration in any industrial operation. Progressive cavity pumps are designed to operate at lower energy levels compared to other pump types, especially when equipped with high-quality parts. By investing in efficient components, companies can reduce their energy consumption, leading to lower operational costs and a smaller environmental footprint.

Application and Industry Impact

1. Food and Beverage Industry

In the food and beverage sector, maintaining product quality and safety is paramount. Progressive cavity pumps are widely used for transferring ingredients, such as sauces, pastes, and dairy products. Investing in reliable pump parts ensures that these products are transported without contamination or alteration, thereby safeguarding the brand’s reputation and compliance with health regulations.

2. Wastewater Treatment

In wastewater treatment facilities, progressive cavity pumps play a vital role in moving sludge and other viscous materials. The ability to handle solids without clogging makes them an ideal choice for these applications. Quality parts ensure that pumps operate efficiently, reducing the risk of breakdowns and costly repairs, which can significantly impact the treatment process.

3. Chemical Manufacturing

The chemical industry often deals with corrosive and hazardous materials. Progressive cavity pumps, equipped with suitable parts, can safely transport these substances without risk of leakage or damage. Investing in durable, resistant materials for pump components is essential for maintaining safety standards and operational efficiency in these environments.

Cost-Benefit Analysis

Initial Investment vs. Long-Term Savings

While the upfront cost of progressive cavity pump parts can be high, it is essential to consider the long-term savings associated with their use. Quality parts typically result in fewer repairs, reduced downtime, and lower energy costs. When evaluating the worth of the investment, companies should weigh these potential savings against the initial expenses.

Impact on Productivity

The reliability and efficiency of progressive cavity pumps directly contribute to overall productivity. By minimizing interruptions and ensuring consistent operation, businesses can optimize their processes and improve output. This increased productivity often translates into higher profits, making the investment in quality parts a sound financial decision.

Conclusion

Investing in progressive cavity pump parts is a decision that should be carefully considered by businesses operating in various industries. The advantages of reliability, versatility, reduced maintenance costs, and energy efficiency demonstrate that these pumps provide significant value. While the initial investment may be substantial, the long-term benefits, including enhanced productivity and lower operational costs, make progressive cavity pumps a worthwhile addition to any industrial setup. Ultimately, the decision to invest in quality parts can lead to improved performance, increased profitability, and a competitive edge in the market.