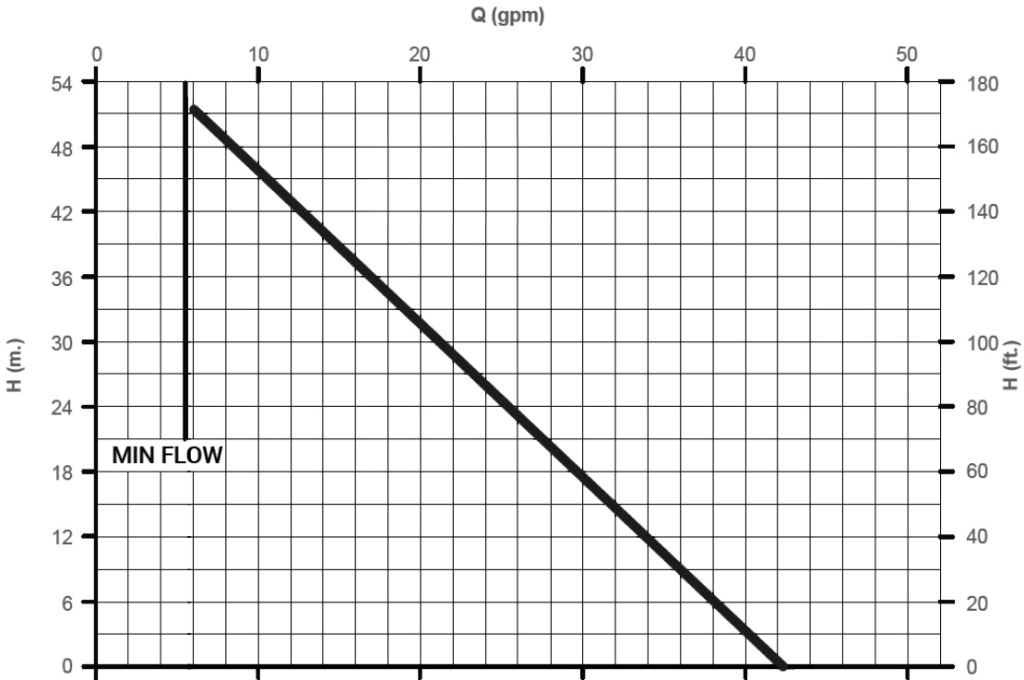

The Moyno Curve is a powerful tool that can help optimize the performance of Moyno progressive cavity pumps. Here’s a step-by-step guide on how to use it effectively to your advantage:

1. Understand the Basics of the Curve

Before using the Moyno Curve, familiarize yourself with its components:

- Flow Rate (Q): The amount of fluid the pump can move, measured in gallons per minute (GPM) or liters per minute (LPM).

- Head (H): The height to which the pump can raise the fluid, measured in feet or meters.

- Efficiency Curve: Indicates how effectively the pump operates at various flow rates.

- NPSHr: The minimum suction pressure required to avoid cavitation.

2. Select the Right Pump

- Use the Moyno Curve to match the pump to your specific application needs by identifying the required flow rate and head.

- Ensure that the selected pump operates within the desired efficiency range to optimize performance.

3. Determine Operating Conditions

- Assess the actual flow rate and head required for your application.

- Plot these values on the Moyno pump Curve to identify the corresponding operating point.

- Ensure that the operating point falls within the optimal range of the curve.

4. Evaluate Efficiency

- Compare the efficiency at your operating point with the efficiency curve.

- Aim for the highest efficiency possible to minimize energy consumption and operational costs.

5. Check NPSHr Requirements

- Verify the Net Positive Suction Head (NPSH) available in your system against the NPSHr indicated on the curve.

- Ensure that your system provides sufficient NPSH to avoid cavitation and potential damage to the pump.

6. Monitor Performance

- Regularly compare actual pump performance data with the Moyno Curve.

- Look for deviations from expected performance, which can indicate issues needing attention.

7. Troubleshoot Issues

- If performance drops or issues arise, use the curve to identify potential causes, such as inadequate suction pressure or exceeding the pump’s flow capacity.

- Analyze and address any discrepancies to restore optimal performance.

8. Optimize the System

- Use insights from the Moyno Curve to make adjustments in your pumping system, such as:

- Modifying the piping configuration.

- Changing the pump speed or size.

- Implementing variable frequency drives (VFD) to control flow rates.

9. Train Personnel

- Ensure that operators and maintenance personnel understand how to read and interpret the Moyno Curve.

- Provide training on using the curve for monitoring and optimizing pump performance.