Progressive cavity pumps are widely used in various industries due to their reliable performance and versatility. When it comes to maintaining these pumps, having access to genuine OEM spare parts is crucial. Progressive cavity OEM spare parts are designed to perfectly fit the pump, ensuring optimal efficiency and prolonging its lifespan. These parts range from stators and rotors to seals and bearings, all engineered to the highest standards. By using authentic OEM parts, you can be confident in your pump’s operation and minimize costly downtime. This comprehensive guide will help you navigate the world of progressive cavity OEM spare parts and maintain your equipment at peak performance.

What Are Progressive Cavity Pumps?

Progressive cavity pumps are positive displacement pumps that use a helical rotor and a stator to move fluids. They are particularly effective for pumping:

- Viscous liquids

- Slurries

- Shear-sensitive substances

Applications

Common industries that utilize progressive cavity pumps include:

- Food and Beverage

- Chemical Processing

- Wastewater Treatment

- Oil and Gas

Importance of Using OEM Spare Parts

Opting for OEM spare parts is crucial for maintaining the performance and reliability of progressive cavity pumps. Here are the key benefits:

1. Quality and Reliability

- Precision Engineering: OEM parts are manufactured to meet the exact specifications of the original equipment, ensuring a perfect fit and functionality.

- Durability: Made from high-quality materials, OEM parts are designed to withstand harsh operational conditions.

2. Performance Consistency

- Optimal Efficiency: OEM components work seamlessly together, helping to maintain the pump’s efficiency and flow consistency.

- Reduced Downtime: Higher reliability of OEM parts leads to less frequent breakdowns and maintenance.

3. Warranty Protection

- Manufacturer Warranty: OEM parts often come with warranties, offering protection against defects and ensuring peace of mind.

Key OEM Spare Parts for Progressive Cavity Pumps

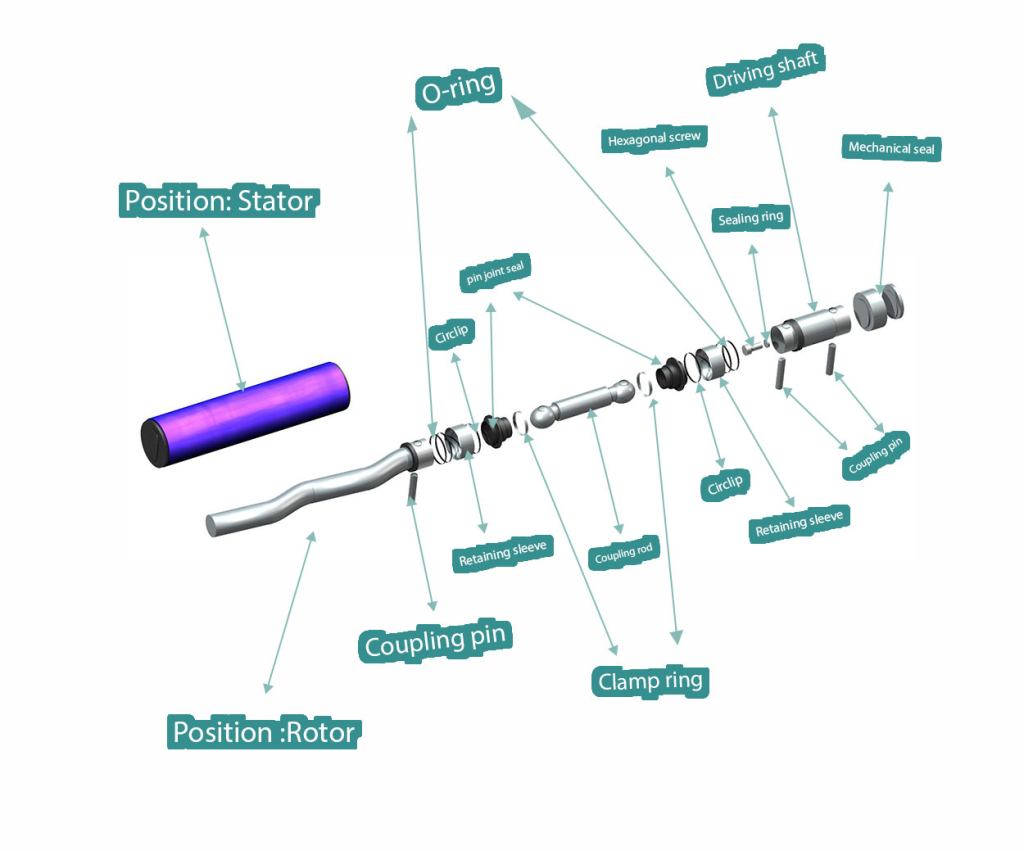

Here’s a detailed look at the essential OEM spare parts used in progressive cavity pumps:

| Spare Part | Description | Function |

|---|---|---|

| Rotor | A helical component that rotates within the stator. | Moves the fluid through the pump. |

| Stator | An elastomeric casing that encases the rotor. | Provides sealing and pressure maintenance. |

| Seals | Components that prevent fluid leakage. | Ensure system integrity and prevent contamination. |

| Bearings | Support the rotor and enable smooth operation. | Reduce friction and wear on moving parts. |

| Suction/Discharge Flanges | Connect the pump to the piping system. | Facilitate fluid intake and discharge. |

| Drive Shaft | Transfers power from the motor to the rotor. | Essential for the pump’s operation. |

Maintenance Practices for Progressive Cavity Pumps

To ensure the optimal performance of your progressive cavity pumps, consider the following maintenance practices:

1. Routine Inspections

- Check Components Regularly: Inspect all parts for wear or damage to catch issues early.

- Monitor Performance Metrics: Keep an eye on flow rates and pressures for any irregularities.

2. Clean Environment

- Avoid Contamination: Maintain cleanliness around the pump and ensure that fluids used are free from contaminants.

- Fluid Quality: Use suitable, clean fluids to minimize wear on internal components.

3. Timely Replacement of Parts

- Replace Worn Components: Address any worn or damaged parts immediately to prevent further issues.

- Choose OEM Parts: Always replace with OEM parts to maintain performance and compatibility.

4. Proper Installation

- Follow Manufacturer Guidelines: Ensure that all parts are installed according to the manufacturer’s instructions to avoid operational failures.

Conclusion

Using OEM spare parts for progressive cavity pumps is vital for maintaining their efficiency, reliability, and longevity. By understanding the key components, their roles, and the importance of regular maintenance, you can ensure optimal performance and minimal downtime. Investing in OEM parts not only safeguards your equipment but also enhances operational efficiency across various industries.