Progressive cavity pumps (PCPs) are vital components in various industrial applications, particularly in the oil and gas, wastewater treatment, and chemical processing sectors. These pumps are designed to handle viscous fluids, and their unique design enables consistent flow rates with minimal pulsation. One crucial part of maintaining the efficiency and reliability of a progressive cavity pump is the rotor. Over time, rotors can wear down due to various factors, necessitating timely repairs to ensure optimal performance.

1. What is a Progressive Cavity Pump?

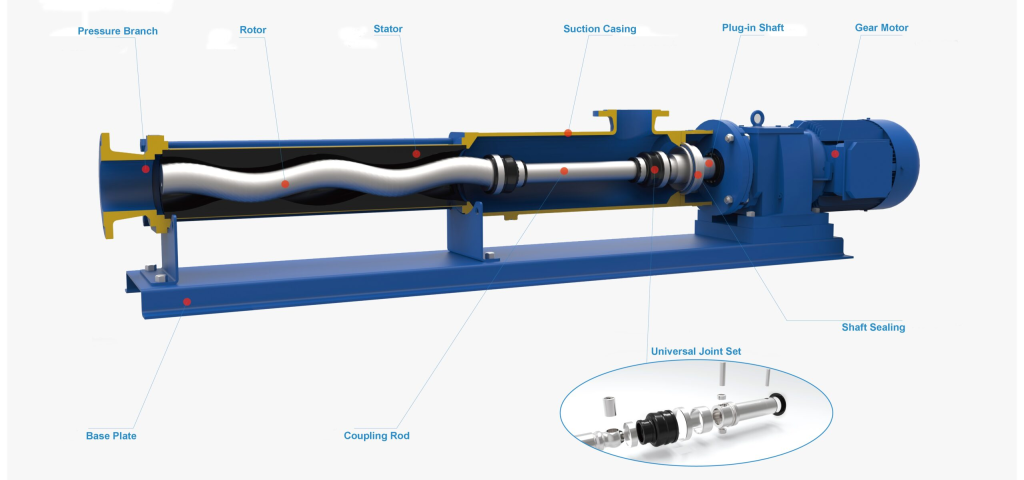

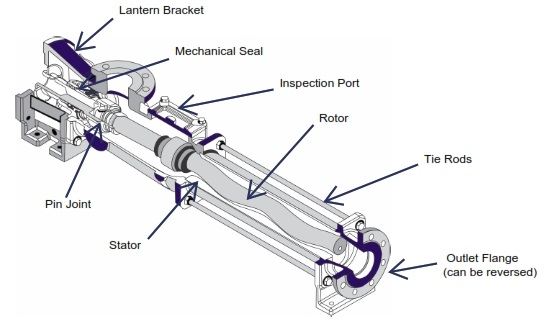

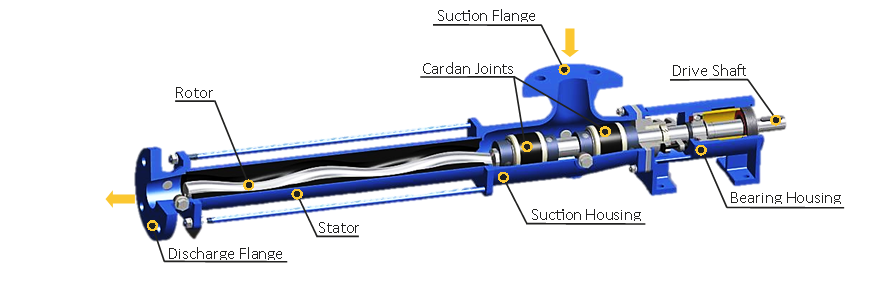

A progressive cavity pump comprises a helical rotor that moves through a stator, creating cavities that transport fluid. The rotor’s rotation causes the fluid to move from the pump’s inlet to its outlet. This mechanism allows the pump to handle thick, viscous fluids that traditional centrifugal pumps may struggle with. As a result, PCPs are commonly used for applications involving heavy slurries, drilling mud, and food processing.

2. Why Rotor Repair is Important

The rotor is a crucial component of the pump and is subject to significant wear over time. Factors such as abrasive materials in the fluid, temperature fluctuations, and operational stresses can contribute to rotor degradation. If a rotor fails, it can lead to a loss of efficiency, increased operational costs, and even complete pump failure. Therefore, understanding the signs that indicate the need for progressive cavity pump rotor repair is essential for maintaining operational efficiency.

3. Signs of Rotor Wear

Identifying wear early can prevent costly downtime. Some common indicators that your progressive cavity pump rotor may need repair include:

- Reduced Flow Rate: A noticeable drop in the flow rate can indicate that the rotor is worn out or damaged.

- Unusual Noise: Grinding or knocking noises during operation may signify rotor misalignment or wear.

- Increased Vibration: Excessive vibration can correlate with rotor issues and could lead to more extensive damage if not addressed.

- Fluid Leaks: Puddles around the pump base or leakage from the pump housing may signal rotor problems.

4. The Repair Process

When it becomes evident that a rotor requires repair, a systematic approach should be taken:

Step 1: Inspection

The first step involves a thorough inspection of the rotor and other components of the pump. Technicians should measure the rotor’s geometric dimensions and check for signs of wear, corrosion, or damage.

Step 2: Disassembly

Carefully disassemble the pump to access the rotor. This process requires precision to ensure that no additional damage occurs during removal.

Step 3: Cleaning

Once disassembled, all parts should be cleaned to remove any buildup of fluids, dirt, or debris. This step is essential for assessing the true condition of the rotor.

Step 4: Evaluation

After cleaning, the rotor should be evaluated. If wear is minimal, re-machining the rotor or applying specialized coatings may suffice. If damage is severe, replacement may be necessary.

Step 5: Reassembly and Testing

After repairs or replacements, the pump should be reassembled carefully. After reassembly, initial tests should be performed to ensure that the pump operates as intended and that the repair has restored its efficiency.

5. Preventative Measures

To extend the lifespan of the rotor and minimize the need for repairs, preventative measures should be implemented. Regular maintenance routines, including lubrication checks, operational monitoring, and timely inspections, can significantly enhance the durability of pump components. Additionally, employing filters to remove abrasive particles from the fluid can help protect the rotor.

Conclusion

Progressive cavity pump rotor repair is a crucial aspect of maintaining the efficiency and reliability of PCPs across various industries. By understanding the importance of this process, recognizing the signs of wear, and implementing effective maintenance strategies, operators can significantly reduce downtime and operational costs. Regular inspections and attention to detail in both operation and maintenance will ensure your progressive cavity pump continues to perform at its best for years to come.